This is a senior design capstone project with the RAAD Lab at Purdue, led by Dr. Laura Blumenschein.

A vine robot is a soft robot with an everting inflatable arm.

Current vine robots rely on a continuous air supply and are subjected to significant leakage. The purpose of this research project is twofold: to develop a space-capable vine robot supported by a closed-loop air circulation system (CLACS) and determine ideal materials to prevent fluid permeation through the arm.

The team was comprised of five Mechanical Engineering students:

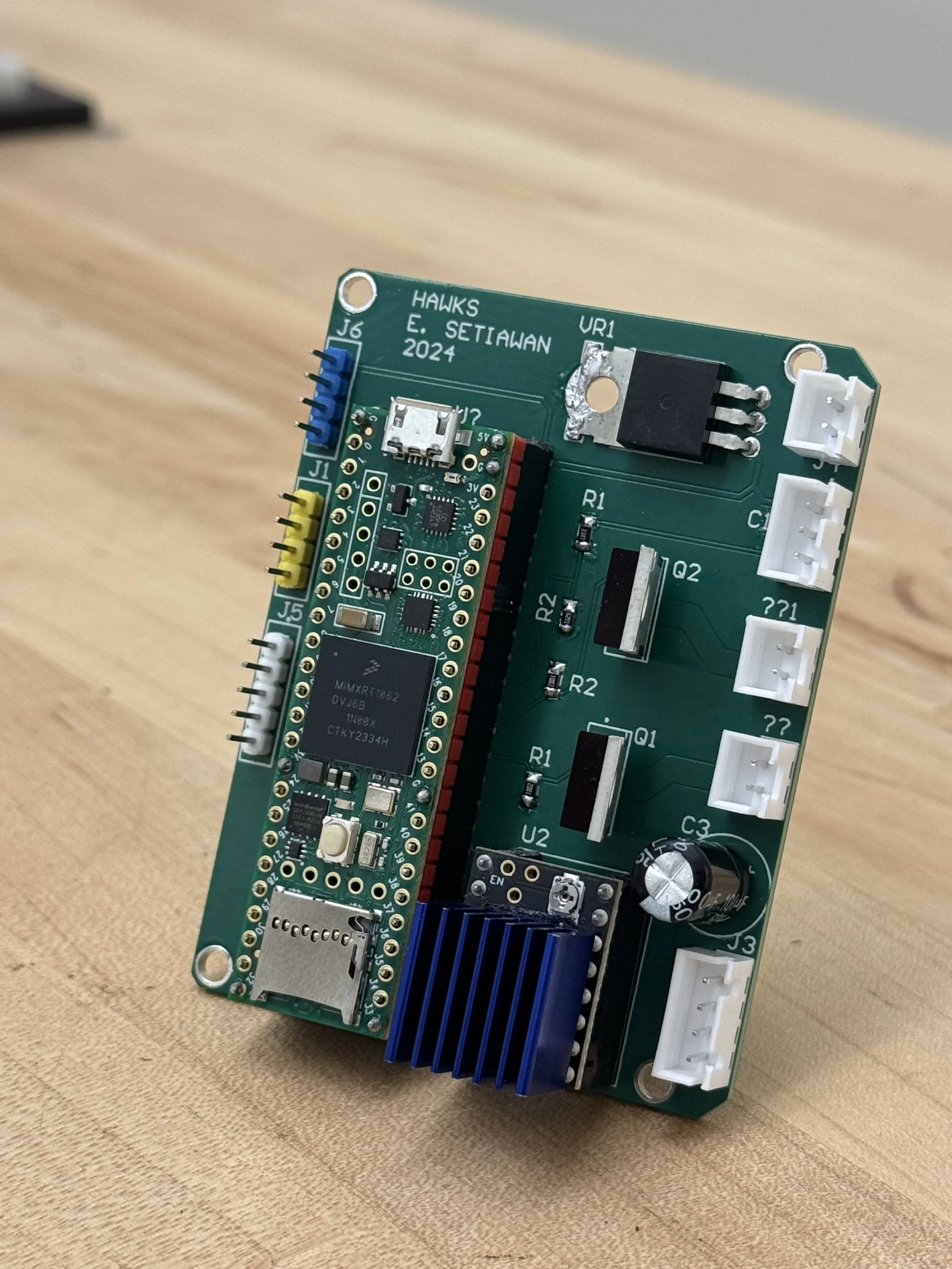

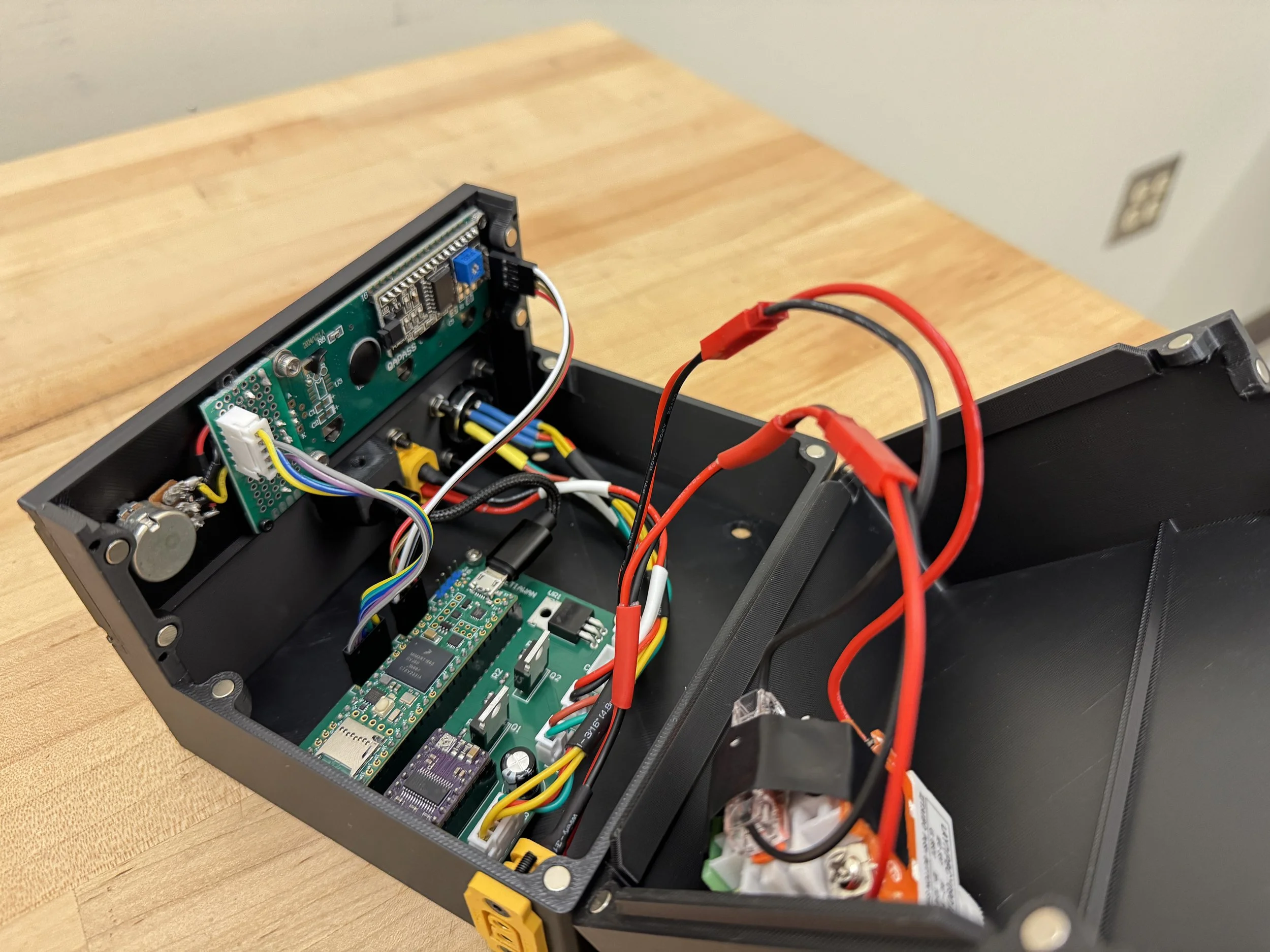

- Enrico Setiawan (me): CLACS architecture, integration and mechanical design

- Griffin Hentzen: Project manager

- Peter Kozerski: Materials research, testing and analysis

- Ilina Adhikari: Chief engineer

- Grace Weisman-Fleischer: Purchasing and manufacturing

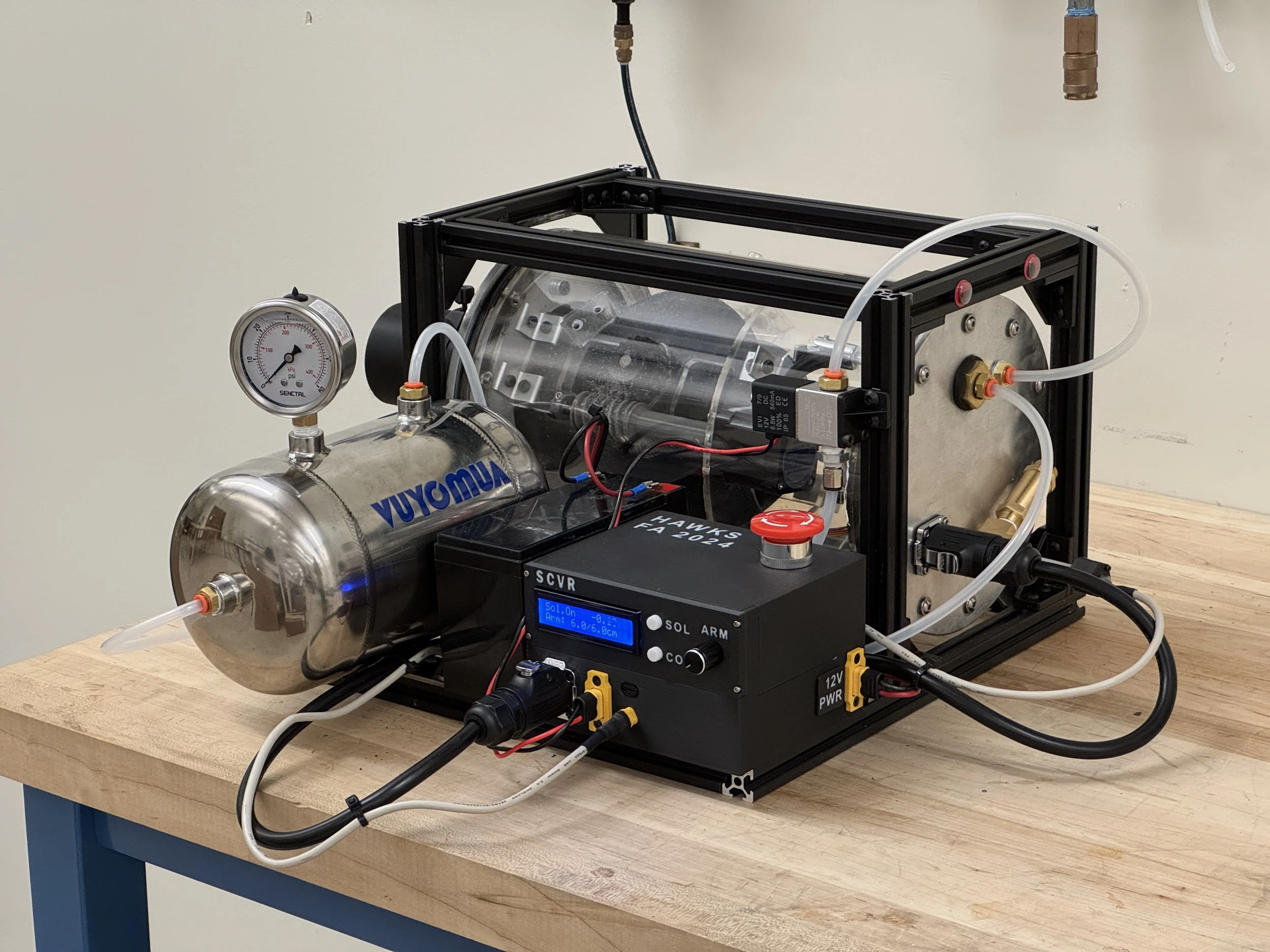

The robot was successfully able to hold pressure at 3 psi with <1 psi pressure drop per 30 seconds of operation and run five full cycles of growth and retraction of a 2 mil LDPE arm using a spool system and control scheme.

The full design report can be found here

This portfolio page will cover my specific contributions which include:

CLACS architecture design

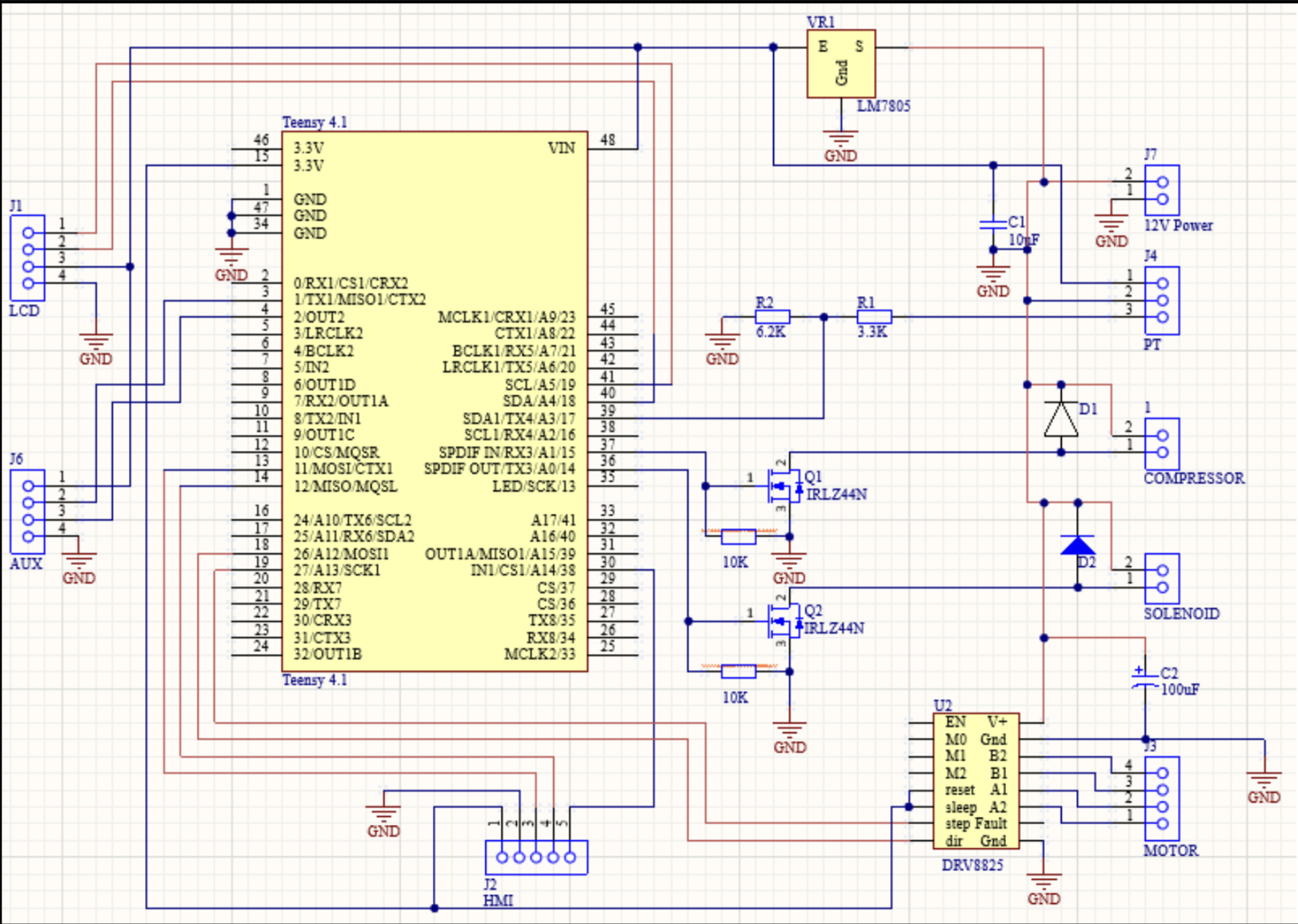

Electronics and control scheme

Bulkhead design

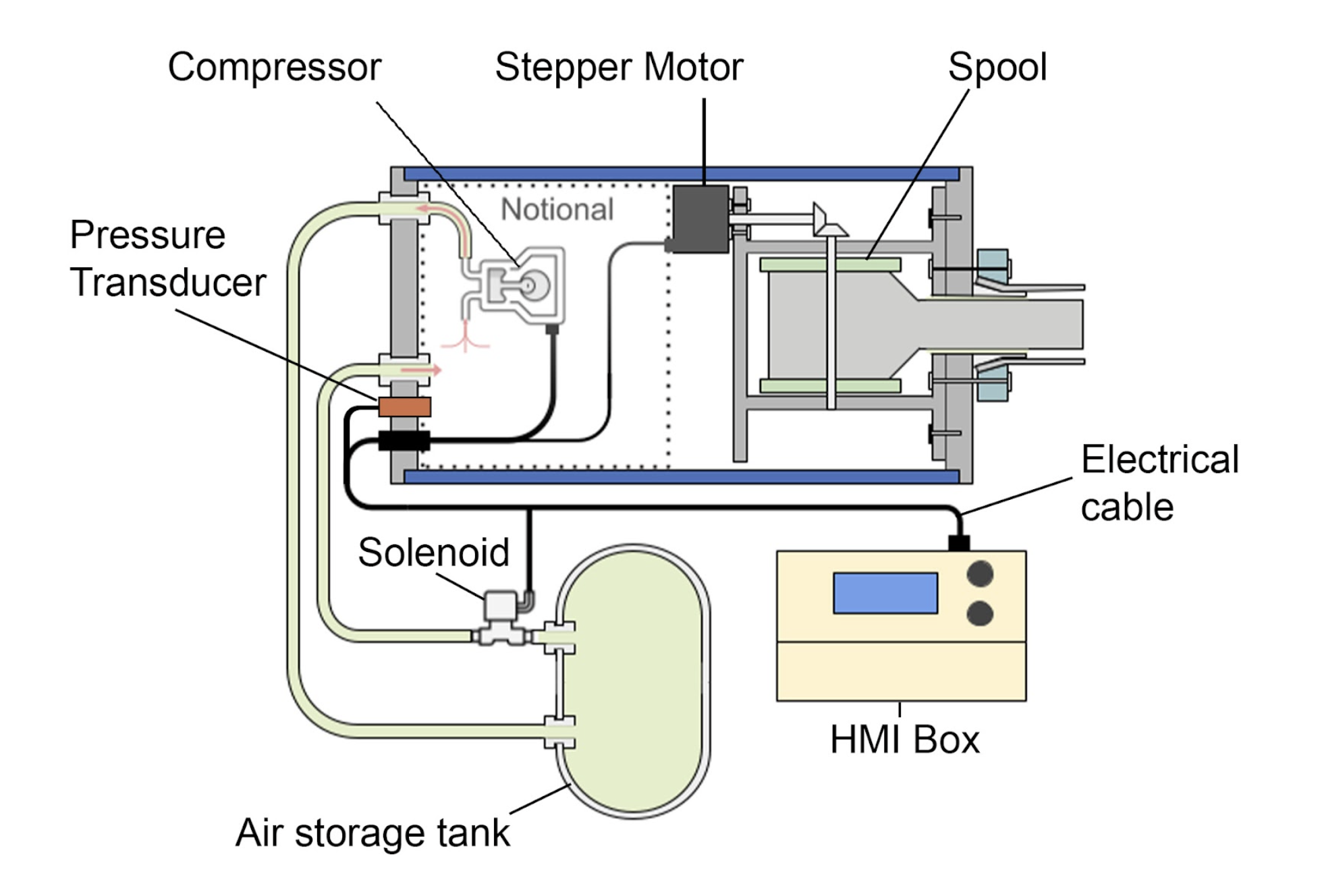

CLACS architecture

Simply put, the purpose of the CLACS (closed loop air circulation system) is to move air from the air storage tank to the vine robot during extension of the robot arm, and from the vine robot back to the air storage tank during retraction.

The CLACS system relies solely on a pressure transducer which reads the internal pressure of the vine robot.

When the robot is commanded to extend the arm, a stepper motor unwinds a spool, increasing the available internal volume of the vine robot and decreasing internal pressure. As this drop in pressure is detected by the pressure transducer, a solenoid valve is opened to allow air to enter from the higher pressure air storage tank.

Conversely, when the robot is commanded to retract the arm, the stepper motor winds the spool, pulling back the arm and decreasing the available internal volume, creating an increase in internal pressure. This increase in pressure triggers the compressor to pump back into the higher pressure air storage tank.

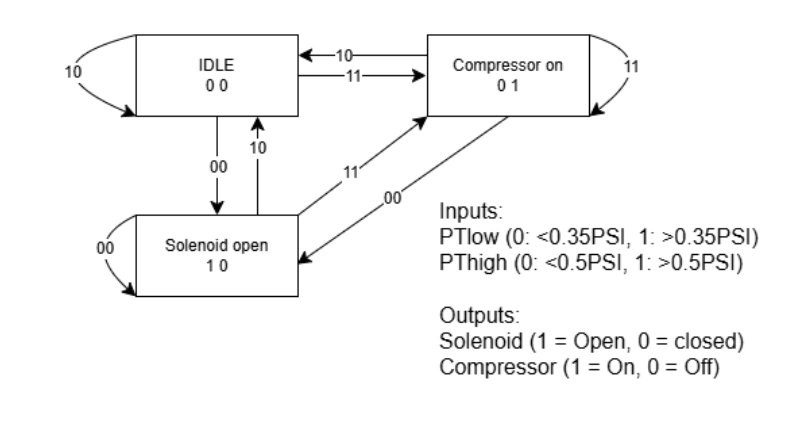

This way, the control loop can be a simple bang-bang controller with a set dead band.

As such, the finite state machine was incredibly simple, comprising of only three states.